हमें कॉल करें : 08045803765

Hoist LOADPIN

38000 आईएनआर/Unit

उत्पाद विवरण:

- रोटेशन टाइप Non-rotating Design

- फोर्कलिफ्ट Compatible with Electric Hoists

- विशेषताएँ IP67 Protection, Maintenance-Free

- कंट्रोल सिस्टम Digital Display / PLC Compatible

- शर्त

- उठाने की क्षमता Up to 30 Tons

- मैक्स। लिफ्टिंग लोड Up to Rated Hoist Capacity

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Compatible with Electric Hoists

- Non-rotating Design

- IP67 Protection, Maintenance-Free

- 24V DC (Sensor Supply)

- Digital Display / PLC Compatible

- Accurate Load Sensing, Overload Protection

- Up to 30 Tons

- Up to Rated Hoist Capacity

- Low Power Requirement

- Depends on Hoist Configuration

व्यापार सूचना

- Vadodara Airport

- , , ,

- प्रति सप्ताह

- हफ़्ता

- , , , , , , , ,

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

उत्पाद वर्णन

FEATURES:

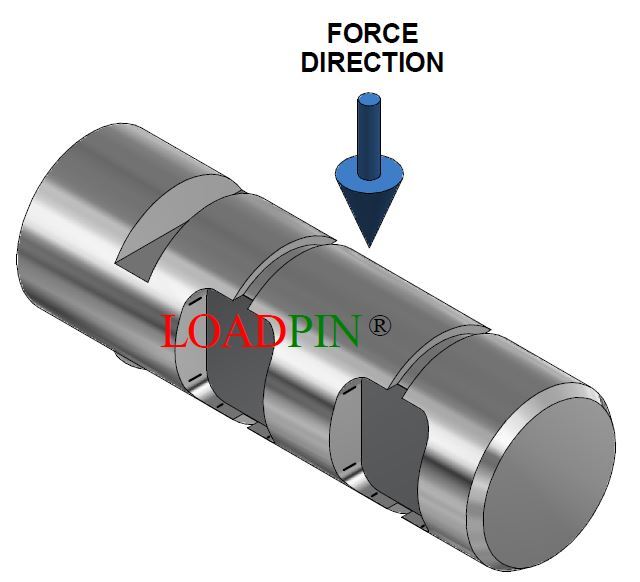

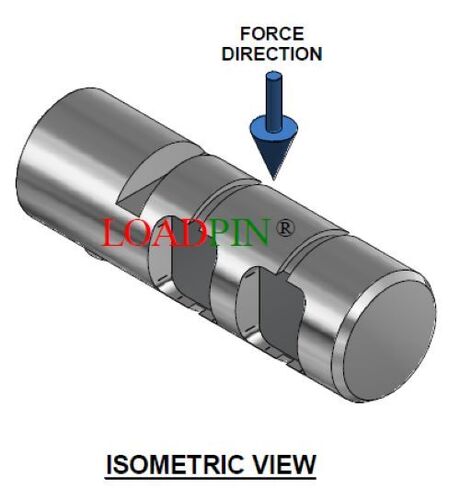

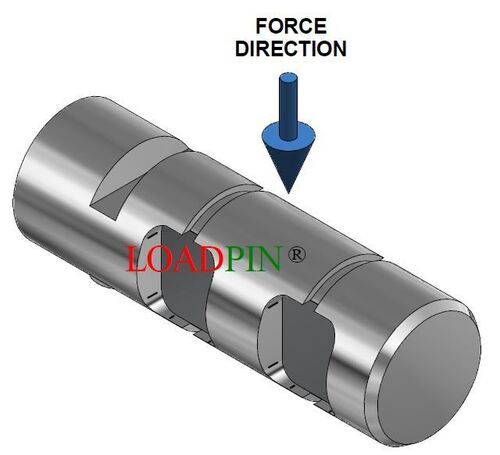

- LOAD POINT = CENTER

- OUTPUT / PRODUCT CUSTOMIZATION AVAILABLE ON REQUEST

- CONCENTRIC ANGULAR LOADING ERROR : CONFIRMS TO CLASS-II

- ECCENTRIC LOADING ERROR : CONFIRMS TO CLASS-III

- SUITABLE FOR REFERENCE STANDARD IS : 9281 (PART 3)-1981, IS : 4169

- LOAD LIMITING DEVICE AS PER IS : 3177:2020

APPLICATIONS:

- WEIGHING INSTRUMENTS / STEEL WEIGHER

- INDUSTRIAL AUTOMATION

- FORCE MEASURING EQUIPMENTS: COMPRESSION / TENSION

- HOPPER - BAG WEIGHING / CONSTRUCTION MACHINERIES

- PROOF LOAD TESTING

- EOT CRANE / GANTRY / HOIST

- ELEVATOR / PASSENGER CUM MATERIAL LIFT

- HANGING PLATFORM / MINI LIFT / TOWER- BUILDER HOIST

- MATERIAL HANDLING EQUIPMENTS

- FOR MOUNTING DETAILS OR INSTRUCTIONS CONTACT US

- DIMENSIONS ARE SUBJECTED TO CHANGE WITHOUT PRIOR NOTICE AND ACCORDING TO THE CUSTOMERS REQUIRED SPECIFICATION. (CUSTOMIZATION)

- WARRANTY : 1 YEAR AGAINST ANY MFG. DEFECT

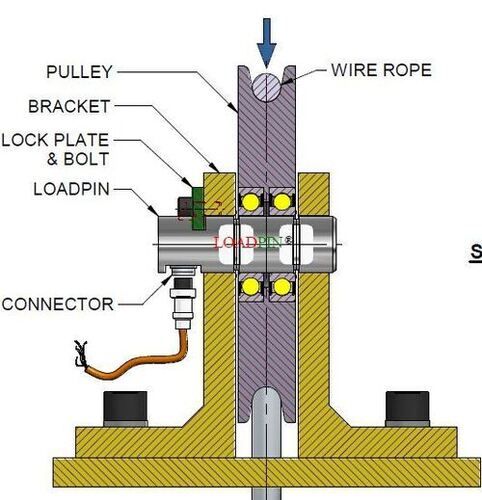

Superior Load Monitoring for Hoists and Cranes

The Hoist LOADPIN is purpose-built for challenging material handling environments. With a capacity of up to 30 tons and IP67 protection, it reliably operates in harsh or dusty conditions. The strain gauge-based sensor provides precise load monitoring, enhancing equipment safety and performance. Its direct pin replacement design simplifies installation on cranes, hoists, or lifting devices, making it an indispensable component for industrial safety and control.

Flexible Integration and Advanced Protection

Supporting both analog (mV/V) and optional digital outputs, the Hoist LOADPIN easily connects to digital displays, PLCs, or control systems. Its customizable cable length and maintenance-free operation suit diverse installation needs. The stainless steel construction provides exceptional resistance to corrosion, while the overload protection feature minimizes risk and ensures long service life in demanding applications.

FAQ's of Hoist LOADPIN:

Q: How is the Hoist LOADPIN installed on lifting equipment?

A: The Hoist LOADPIN is designed for direct pin replacement. Simply remove the existing load-bearing pin on your hoist or crane and insert the LOADPIN in its place, ensuring a secure fit and accurate load sensing, with minimal modification required.Q: What benefits does IP67 waterproof and dustproof protection provide?

A: IP67 rating ensures the LOADPIN is highly resistant to water immersion and dust ingress, making it suitable for outdoor or harsh industrial environments, and ensuring reliable operation regardless of weather or site conditions.Q: What is the correct operating temperature range for the Hoist LOADPIN?

A: The Hoist LOADPIN is engineered to operate reliably between -20C and +60C, accommodating most industrial, warehouse, or outdoor lifting operations throughout the year.Q: Where can the Hoist LOADPIN be used?

A: This load pin is suitable for use in cranes, hoists, forklifts, lifting devices, and various industrial settings in need of precise load monitoring and safety control, especially where electric hoists are used.Q: What type of output signals does the Hoist LOADPIN provide?

A: The sensor delivers analog output (mV/V) by default and offers an optional digital output for interface with modern control systems such as PLCs or digital displays, ensuring compatibility with most control architectures.Q: What is the accuracy class of the Hoist LOADPIN, and why is it important?

A: With an accuracy class of 0.5% of Full Scale, the LOADPIN provides highly reliable readings, critical for applications where safety and exact load measurement are essential to prevent overload and ensure operational efficiency.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email