Call Us : 08045803765

Platform Load Cells

35.00 USD ($)/Piece

Product Details:

- Dimension (L*W*H) 75x75x190 Millimeter (mm)

- Weight 7 Kilograms (kg)

- Operate Method Wheatstone Bridge Principle

- Application Industrial Automation, Weighing, Testing and Measuring.

- Voltage 10 Volt (v)

- Classification Class 3

- Material Alloy Tool Steel

- Click to View more

X

Platform Load Cells Price And Quantity

- 35.00 USD ($)/Piece

- 1 Piece

Platform Load Cells Product Specifications

- 75x75x190 Millimeter (mm)

- 10 VDC Volt (V)

- 0.05 %

- 0 to 50 Celsius (oC)

- 7 Kilograms (kg)

- Analog Sensor

- Compression - Point Load

- Industrial Automation, Weighing, Testing and Measuring.

- Wheatstone Bridge Principle

- Class 3

- 10 Volt (v)

- -10 to 70 Celsius (oC)

- Single Point Load

- Alloy Tool Steel

- Resistance Sensor

- 0 to 50 Celsius (oC)

- Electroless Nickle Plated

Platform Load Cells Trade Information

- NhavaSheva

- 200 Piece Per Week

- 30 Days

- Packed in Corrugated Boxes : 4pcs / Box

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Nagaland, Jharkhand, Madhya Pradesh, Punjab, Tamil Nadu, Goa, Mizoram, Telangana, Bihar, Central India, West India, Pondicherry, Gujarat, West Bengal, Assam, Arunachal Pradesh, Kerala, Jammu and Kashmir, South India, Meghalaya, Manipur, Delhi, Tripura, East India, Sikkim, Odisha, Maharashtra, Andhra Pradesh, Rajasthan, Haryana, Uttar Pradesh, Karnataka, North India, Chhattisgarh, All India

- Ministry MSME's ZED BRONZE Certificate through Quality Council of India.

Product Description

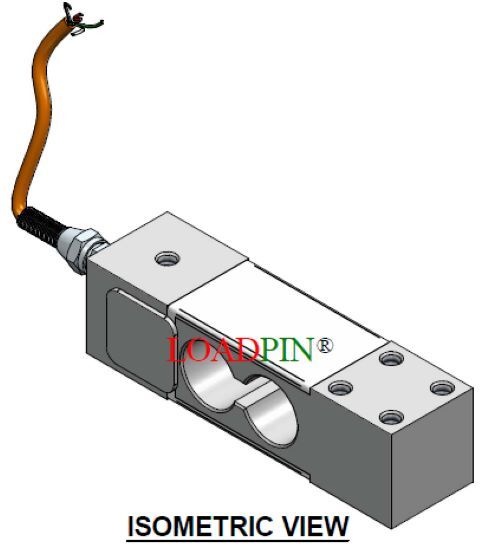

Platform Load Cells

Applications:

-

Large platform scales

-

Hanging scales

-

Check weighing

Features:

-

Capacities: 500-3000 KG

-

Low profile for plate form scale

-

Electroless nickel plated alloy steel construction

-

IP65 protection

-

Complete environmental protection

-

Platform size 1000 x 1000 mm

SPECIFICATION

| STANDARD CAPACITIES |

:500,1000,1500,2000,2500,3000. |

| EXCITATION VOLTAGE | :10VDC TO 15VDC |

| RATED OUTPUT |

:2.0 mv/v |

| INPUT RESISTANCE |

:392 +- 10 Ohms |

| OUTPUT RESISTANCE |

:350 +- 3.0 Ohms |

| CREEP (30 MINUTES) |

:<+- 0.03% Fso |

| ZERO BALANCE |

:+-1.0% Fso |

| NON-REPEATABILITY |

:<+-0.01% Fso |

| HYSTERESIS |

:<+-0.02% Fso |

| NON-LINEARITY |

:<+-0.25% Fso |

| SAFE OVER LOAD |

:150% Of Rated Capacity |

| ULTIMATE OVER LOAD |

:250% Of Rated Capacity |

| ALLOWABLE SIDE LOAD |

:50% Of Rated Capacity |

| TEMPERATURE EFFECT ON O.P. |

:<0.0015% FsooC |

| TEMPERATURE EFFECT ON ZERO |

:<0.0020% FsooC |

| ENVIRONMENTAL PROTECTION |

:IP65 |

Published specifications & dimensions are subject to change without notice.

For more details, feel free to contact us.

Precision You Can Rely On

With an outstanding 0.05% accuracy, these load cells deliver precise readings essential for quality control and measurement in industrial and laboratory environments. The use of Wheatstone Bridge circuitry ensures consistent output, minimizing error and drift even during continuous use.

Durable Construction for Demanding Workspaces

Crafted from alloy tool steel and coated with electroless nickel, our platform load cells are both rugged and corrosion-resistant. Designed to withstand weights up to 7 kg, they maintain stable performance in harsh industrial settings, ensuring your investments last longer.

Versatile Applications in Automation and Testing

These load cells are optimized for industrial automation, weighing platforms, and measuring processes across diverse industries. Their compact size allows for seamless integration, and they function reliably within the specified operating temperature, supporting critical processes efficiently.

FAQs of Platform Load Cells:

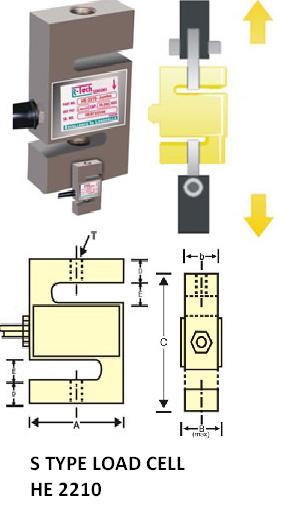

Q: How does the platform load cell operate and what is its fundamental principle?

A: The platform load cell operates using the Wheatstone Bridge Principle, a well-known resistance sensor theory. When a force or load is applied, the resulting mechanical strain changes the electrical resistance, which is then converted into an analog output for precise measurement.Q: What are the main benefits of using a compression, point-load platform load cell in industrial automation?

A: Compression, point-load platform load cells ensure exceptional accuracy (0.05%) and repeatability, essential for maintaining product quality in industrial automation. Their robust construction and corrosion resistance enhance longevity and minimize maintenance needs, optimizing operational efficiency.Q: When is it necessary to use a compensated temperature range load cell?

A: A compensated temperature range load cell should be used when measurements need to remain accurate despite ambient temperature changes. This model maintains accuracy within an operating and compensated range of 0 to 50C, ideal for variable industrial environments.Q: Where can these load cells be installed and what industries benefit most?

A: These load cells can be integrated into platforms, assembly lines, and testing stations in sectors such as manufacturing, logistics, and material testing. Their compact 75x75x190 mm size makes them suitable for space-sensitive applications throughout industrial automation and weighing processes.Q: How is the analog output from the load cell utilized in measurement processes?

A: The analog output represents the force or load applied to the platform. This signal is typically transmitted to controllers or data acquisition systems, enabling real-time monitoring and accurate feedback within automation, weighing, or measurement operations.Q: What is the process for proper installation and optimal performance?

A: For optimal results, the load cell should be installed on a stable, appropriately dimensioned platform and correctly wired to your measurement circuitry. Follow manufacturer guidelines for voltage (10 VDC) and ensure that the installation environment remains within the specified temperature and load limits.Q: What storage conditions are recommended to ensure longevity?

A: The load cell should be stored between -10 to 70C in a dry, dust-free environment. Proper storage safeguards the internal mechanisms and maintains accuracy, helping the load cell deliver reliable results throughout its service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email