Call Us : 08045803765

Concrete Batch Controller

41600 INR/Piece

Product Details:

- Sensor Type Load Cells, Pressure Transducers, Proximity Sensors

- Mounting Type Panel Mount

- Operating Temperature -10C to 50C Celsius (oC)

- Application Concrete Batching, Precast Concrete, RMC

- Rated Voltage 24 VDC Volt (V)

- Display Type LCD, Digital

- Material Copper

- Click to View more

X

Concrete Batch Controller Price And Quantity

- 41600 INR/Piece

- 1 Piece

Concrete Batch Controller Product Specifications

- 24 VDC Volt (V)

- Load Cells, Pressure Transducers, Proximity Sensors

- Copper

- Concrete Batching, Precast Concrete, RMC

- -10C to 50C Celsius (oC)

- LCD, Digital

- Panel Mount

Concrete Batch Controller Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 5000 Piece Per Month

- Days

- Packed in C/R Box, Customized for above product.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Ministry MSME's ZED BRONZE Certificate through Quality Council of India.

Product Description

CONCRETE BATCH CONTROLLER

Key Features:

- Robust structure

- Ease of maintenance

- Modular design providing flexibility to adopt different layout requirements

- Deliver consistent quality concrete and are most preferred in the RMC industry

- CONCRETE CONTROLLER a Micro-controller based batch control unit.

- It is configured for a concrete batch mix plant applications.

- It can control feeding of multiple components with the help of load cell inputs, Status inputs and control outputs.

Precision and Versatility for Concrete Applications

This batch controller caters to diverse needs within concrete batching, precast concrete, and RMC environments. Its compatibility with advanced sensors allows for seamless data acquisition and ensures batch consistency. This level of control enhances material management, minimizes waste, and enables higher-quality concrete outputs.

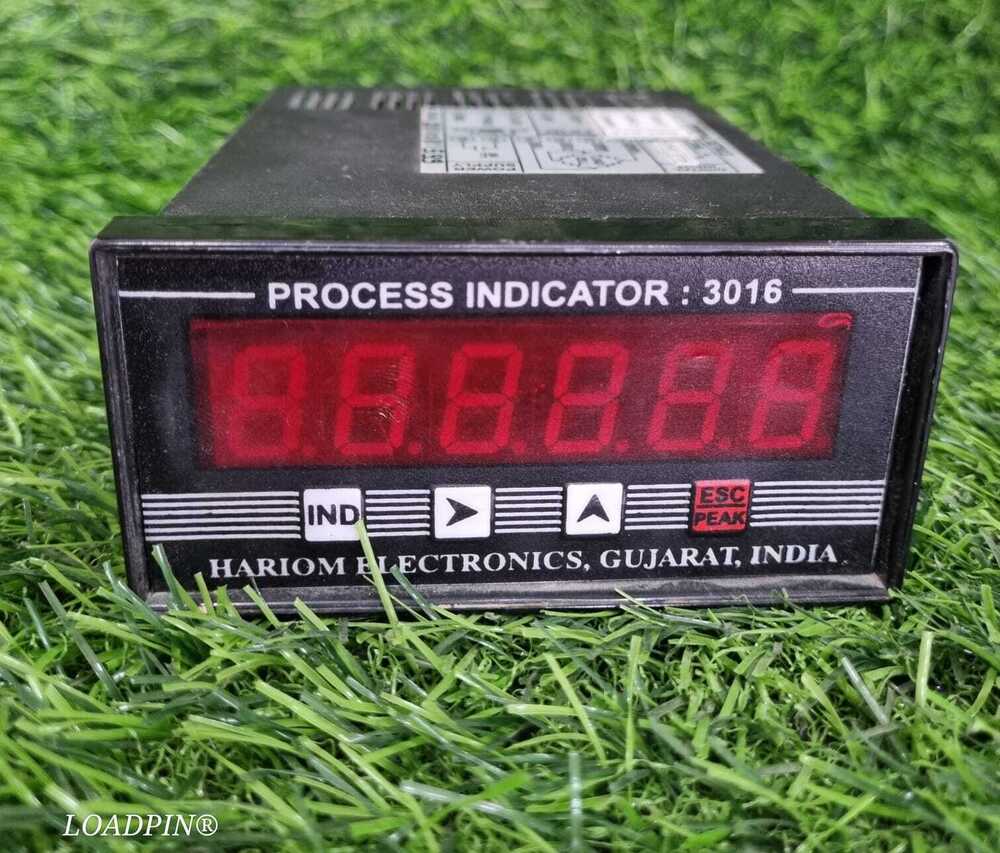

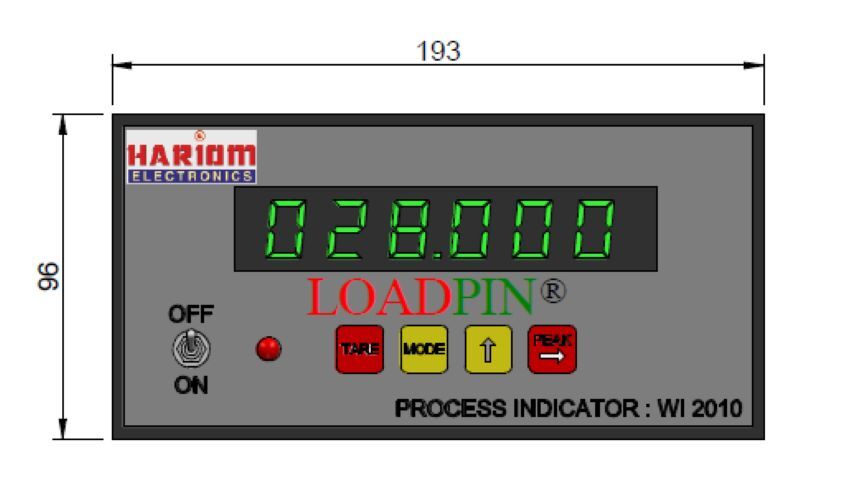

User-Friendly Display and Reliable Operation

Featuring both LCD and digital display types, users gain clear visibility over every batching parameter. The controller is designed for a simple panel mount installation and reliable function across a wide temperature range, making it ideal for demanding workspaces. The copper construction elevates its robustness, promising longevity.

FAQs of Concrete Batch Controller:

Q: How does the Concrete Batch Controller improve batching accuracy?

A: By using load cells, pressure transducers, and proximity sensors, the controller provides real-time data for precise measurement and batching control, significantly reducing material discrepancies and ensuring consistent concrete quality.Q: What is the process for installing this batch controller in a plant?

A: Installation involves a panel mount setup, connecting the controller to load cells and sensors already integrated into batching systems. Once connected to a 24 VDC power supply, the system settings can be configured via the digital LCD interface.Q: When should the controller be used in concrete batching applications?

A: This controller is ideal for use during automated or semi-automated batching operations, particularly when high precision and monitoring are necessary, such as in precast units or RMC plants.Q: Where can this controller be effectively utilized?

A: It can be used in a wide range of environmentssuch as concrete batching plants, precast concrete manufacturing, and ready-mixed concrete operationsanywhere requiring batch monitoring and control within the specified temperature range.Q: What are the primary benefits of using a load cell-based batch controller?

A: Load cell integration enhances weight measurement accuracy, leading to improved batch consistency, optimized resource use, less material waste, and stronger, more reliable concrete products.Q: How does the IP20 rating impact the controllers usage environment?

A: An IP20 rating means the controller is protected against solid objects over 12.5mm but not against water, so it is best installed in dry, protected indoor industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email